The Most Common Sub-Metering Errors (and How to Avoid Them)

PUBLISHED MAY 30, 2025

It is not uncommon for our firm to receive calls from sub-metering companies and firms that encounter issues mid-project or during reverifications, such as meter communication failures, mismatched hardware, or failed testing.

Our experts at Verification and Inspection Professionals (VIP) Inc. have found that the majority of these issues stem from the fact that sub-metering was not approached holistically, as a pillar of a property’s overall smart infrastructure.

These are mistakes your projects cannot afford to suffer, because the reality is — when sub-metering goes wrong, it’s expensive.

It delays your ability to bill, causes compliance issues, and costly, frustrating rework. And in the worst cases, it can damage your reputation with property managers and owners and lead to failed contract renewals and competitors swooping in to take over a property contract.

Avoiding these pitfalls requires expertise and precision from your install teams, who should support the project by:

- Reviewing and identifying site drawings to ensure compatibility with sub-metering requirements.

- Selecting the right meter types (electricity, water, gas, thermal)

- Integrating meter specifications and communication

- Documenting every meter point and

- Rigorously verifying S-E-04 specifications.

VIP Does Sub-Metering System Installations Right

VIP is a leader in providing end-to-end sub-metering services. We assist sub-metering providers, utility companies, property management companies, and engineering firms in ensuring that new builds and retrofits get sub-metering integration done right, the first time. We’re also there when projects need to be rescued.

Real-Time Software to Keep Projects on Track

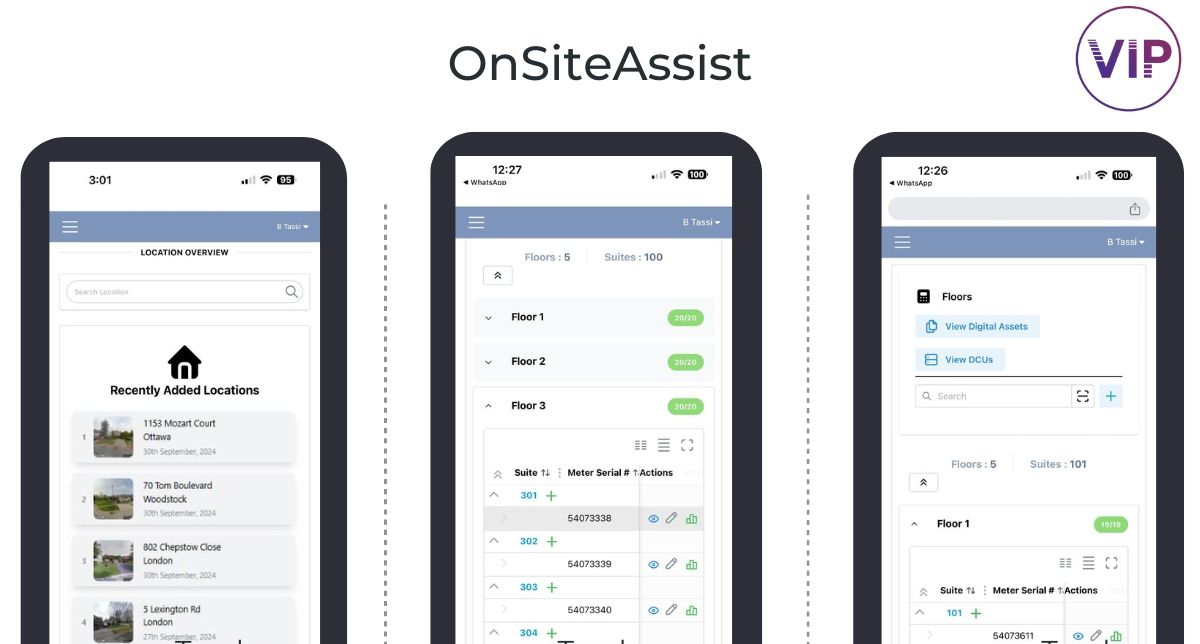

At VIP, preventing costly sub-metering errors starts with transparency. That’s why we equip every project with two of our most powerful tools: OnSiteAssist and the Status Dashboard.

These tools give real-time visibility into every stage of your sub-metering rollout — from installation and commissioning to verification and final handover. This liberates your time and cognitive energy dedicated to chasing down updates from electricians, plumbers, procurement teams, or technicians. Operations, sales, and finance teams can all see live progress at a glance.

This level of visibility allows you to supervise a job site without requiring you to be standing over someone’s shoulder. You’ll know exactly what’s happening on-site — what’s been installed, what’s verified, and what’s still in progress — without having to ask.

Ready to Ace Your Next Sub-Metering Project?

Contact our Experts

The Common Sub-Metering Errors You Must Avoid

Here are some of the most common sub-metering errors we see — and how our team helps avoid them through a coordinated, holistic approach.

1. Limited Sub-Metering System Design

Sub-metering for new construction projects moves fast — and mistakes at the design stage can create long delays if overlooked. Working with poor system layouts can lead to sub-metering maintenance inefficiencies in the future, cost overruns, and compliance failures down the road.

VIP helps you get ahead of those issues by engaging early.

We provide sub-metering consultation services and work directly with electrical and mechanical designers to ensure the project includes everything needed for a fully functional, regulation-compliant sub-metering system that supports a property’s long-term profitability and sustainability.

Getting a firm like VIP involved means fewer surprises later. You avoid setbacks from redesigns, change orders, and last-minute compliance issues. And more importantly, your sub-metering system is set up right — accurate, accessible, and ready to bill when you need to be.

How This Looks

When a client sends us their IFC sets, we review the final scope.

Are they going with wired or wireless meters? What communication protocols are needed, wired or wireless? That gives us our baseline.

From there, we design the whole system, factoring in the best meter types, CT sizing, network infrastructure, comms, and the integration of meters with the MDMS (meter data management system.

Our experts mark up the drawings and send them to the developer’s consultants for review. Thanks to our field experience and technical accuracy, nine times out of ten, those approvals come through on the first pass.

2. Sub-Metering Procurement That Doesn’t Fit the System

Procurement is one of the most common points where sub-metering projects hit a wall — usually because key decisions weren’t finalized during the planning phase.

Sub-metering systems aren’t one-size-fits-all. The meters you use need to align with the building’s design, load profiles, and communication infrastructure. Procurement also must align with a project’s timeline and budget.

If you're implementing multiple systems — electric, water, gas, and thermal — each needs to support the right network protocols and collectively integrate with your MDMS or building automation platform. More importantly, the installation location must be accurately chosen and done.

Misalignment at this stage will severely complicate integration and your ability to efficiently manage a system long-term.

For example, electrical meter panels must have the correct number and type of CTs to support your design-build. If that’s overlooked, your entire electrical metering strategy may need to be reworked — often after the panel is already built.

We’ve seen projects delayed for weeks because the selected meters weren’t compatible with the building’s electrical infrastructure or other utility systems. In some cases, clients sourced locked-in proprietary equipment incompatible with asset management and data systems.

How We Help It

VIP serves as your sub-metering system’s stop-gap during construction. We source the right equipment, at the right time, so that your project moves forward without surprises, and avoid the need to rip and replace what should’ve been right from the start.

We review a property’s full specs, including communication standards and any head-end system specification, to ensure the gear you receive is:

- Open-protocol and integration-ready

- Matched to your building’s voltage class, load types, and panel design

- Compliant with Measurement Canada and local regulatory requirements

- Delivered on time and backed by our installation and verification workflow

We work with over 150 meter types (including gas, water, thermal, and electrical meters) and brands and consider all options to determine which technology is the best fit for your specific project.

3. Inaccurate and Uncompetitive Sub-Metering Bids

Another early misstep we see in sub-metering projects is pricing a job without a clear understanding of what's actually required.

This begins at the RFP phase. Contractors ask for bids and expect a quote from their sales rep. If that team doesn’t yet have a full technical picture of the project or is unfamiliar with a building type or the local regulatory landscape, this can lead to serious discrepancies once work begins — strained relationships, cost overruns, change orders, and penalties for not meeting project timelines.

How We Help

VIP helps clients give the most competitive quotes possible while maintaining cost accuracy. Our consulting services help sub-metering companies review proposals and specifications to understand a project’s scope — whether it’s new construction or a retrofit system.

4. Poor Sub-Metering Installations That Cost You Later

One of the issues we encounter quite often on a job site are wrong installations.

We will show up ready to verify or commission a system, and realize an entire installation has been done incorrectly.

Even when instructions are provided, installers who are unfamiliar with equipment or sub-metering regulations can make errors, such as installing backwards CTs, incorrectly piping thermal meters, or positioning wireless units outside the signal range.

We’ve seen these types of mistakes across meter types — electrical, water, thermal, gas — and they typically stem from a contractor’s limited experience with a specific design or project location.

These types of setbacks are damaging and completely avoidable. If undetected before occupancy, these problems throw off billing accuracy or even lead to compliance failure. We've seen developers lose one to two months of billable usage due to unaddressed installation errors in their sub-metering systems.

Meanwhile, the utility provider doesn’t wait — they’ll charge based on bulk consumption, regardless of whether your meters are functioning or not.

How We Help

VIP protects clients from this kind of liability at several levels, from installation to total project management to final verification.

We craft site-specific installation drawings and stay closely involved during installation to ensure meter commission and system installation are done right. Our team completes S-E-04 inspections and rigorous system testing to ensure every device is installed to spec, compliant, and reporting properly to your MDMS before handover.

We ensure that meters are installed where they are supposed to be installed so that they are collecting precise data - not more or less than they should be collecting.

5. Disorganized or Incomplete Sub-Metering Documentation

Sub-metering projects generate a lot of moving parts — equipment specs, installation drawings, tenant data, and regulatory filings. Without a clear system to manage all of it, details slip through the cracks. That’s where billing errors, failed audits, and integration problems start.

What many clients don’t realize is how important clean documentation is from the point of commission.

From the first floor to the 40th floor, meters must be accurately mapped to corresponding units. Floor by floor, tenant by tenant — and easily updated when a meter unit is exchanged.

If that information isn’t collected, labeled, and entered into the MDMS properly, billing can’t happen. Worse, any audit or service request down the line becomes a logistical nightmare.

How We Help

VIP automates workflow processes to deliver consistent, high-quality data free from human error.

Every party involved in delivering sub-metering projects works on a centralized ERP system, where everything is properly catalogued. This means you don't have to worry about missed steps, errors, or misplaced or out-of-date documents and certificates.

We Do it Right — Commissioning, Verification, Project Management, Documentation

VIP, based in Toronto, is the trusted partner behind sub-metering companies across Canada — empowering them to tackle new construction and retrofit sub-metering system installations without learning curve or risk.

Our field experts and engineers deliver operational confidence from consultation, planning, installation and system maintenance.

Ace Your Next Sub-Metering Installation

Talk We Our Experts